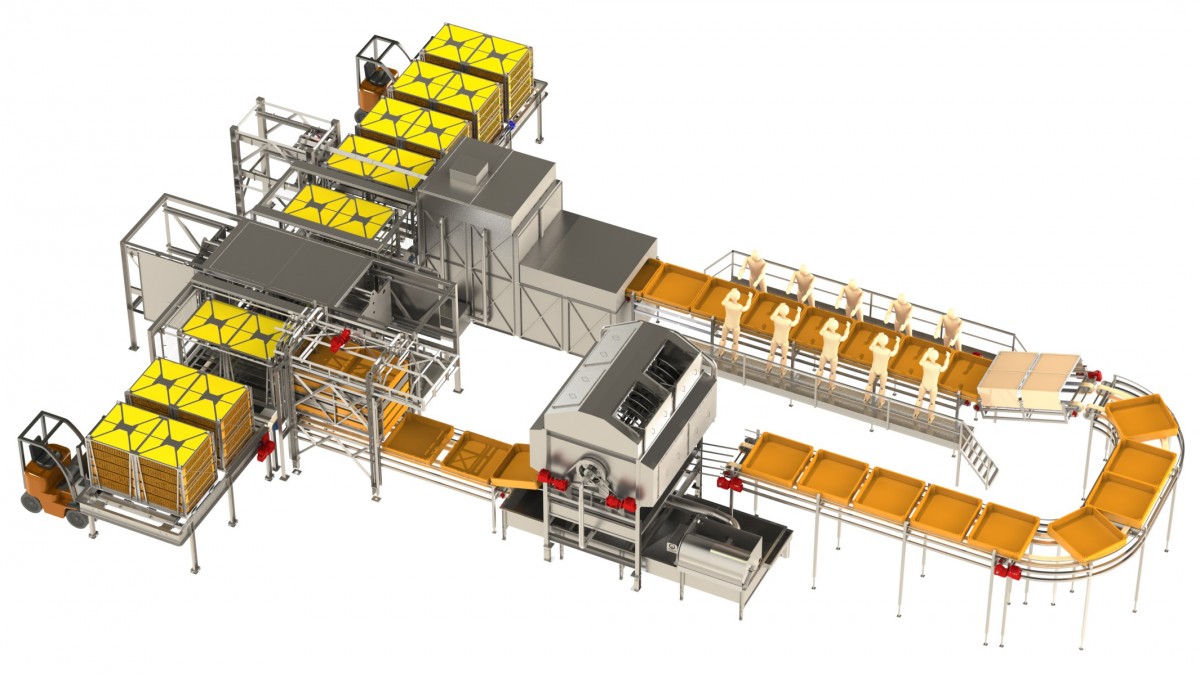

Meyn Maxiload Twin LBH System

HIGH PRODUCTIVITY IN A COMPACT FOOTPRINT

Thanks to the new module design, you can get an optimized layout, compared with the bird handling capacity. in other terms, the footprint of the Twin bird handling system is the most compact when compared with what the market is able to offer today.

A reduced footprint is one of the major achievements of Meyn Maxiload Twin system.

Meyn Maxiload Twin allows different ways of arranging the line. In case you want to reach very high speeds, two parallel killing lines may be installed and they will be fed from the same module. In this case, drawers are extracted from opposite sides, in order to feed the two parallel lines. Modules can be handled as superposed, again in order to reach higher speeds.

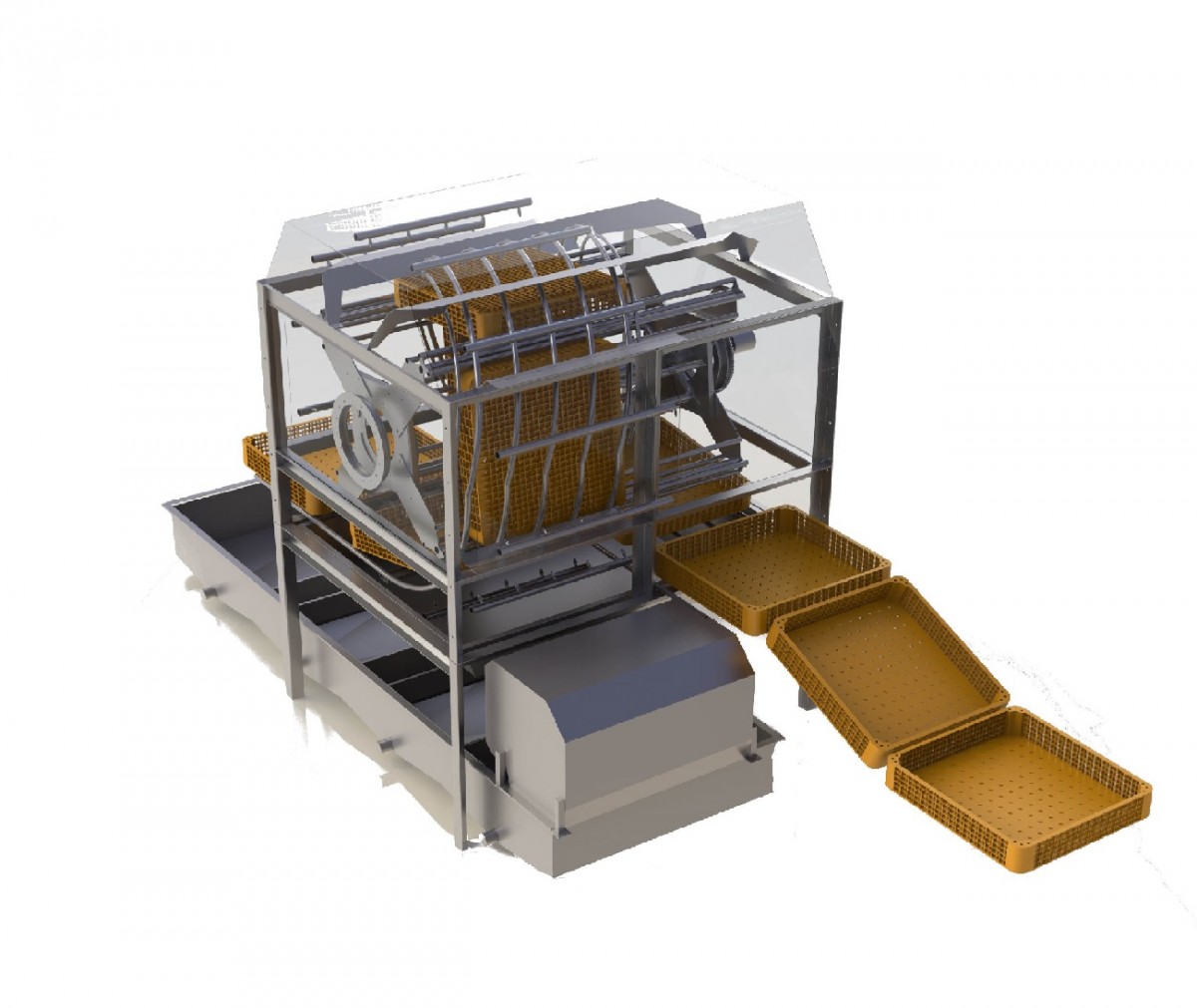

THE SPIRAL DRAWER WASHER

The New Spiral Drawer Washer features a very compact design, resulting in a small foot print and in getting the positive effect of a repeated wash at very high volumes of water of all the surfaces of the drawers.

A separated prewashing section, at high pressure and low volume of water, removes the biggest part of dirt from the drawers.

An external rotor which is in continuous rotation at variable speed is transporting the drawers through the washing section, exposing the internal surface of the drawers in all positions to the internal rotor, which spins freely while carrying a set of washing nozzles.

An external set of fixed nozzles washes the external surfaces while the drawers change positions continuously.

An exit section provides a final rinsing with clean water to be recycled in the main section. An advanced fi ltering system with rotary strainer, combined with a sand and mud decanting system, completes the process.